System Properties:

Steam generator for waste heat recovery from flue gas. The steam generator takes heat energy from the clean gas stream and thus generates steam. Any existing fired steam generators thus become obsolete or can be used as a back-up. The waste heat recovery with this plant saves CO2 and thus sustainably protects the environment.

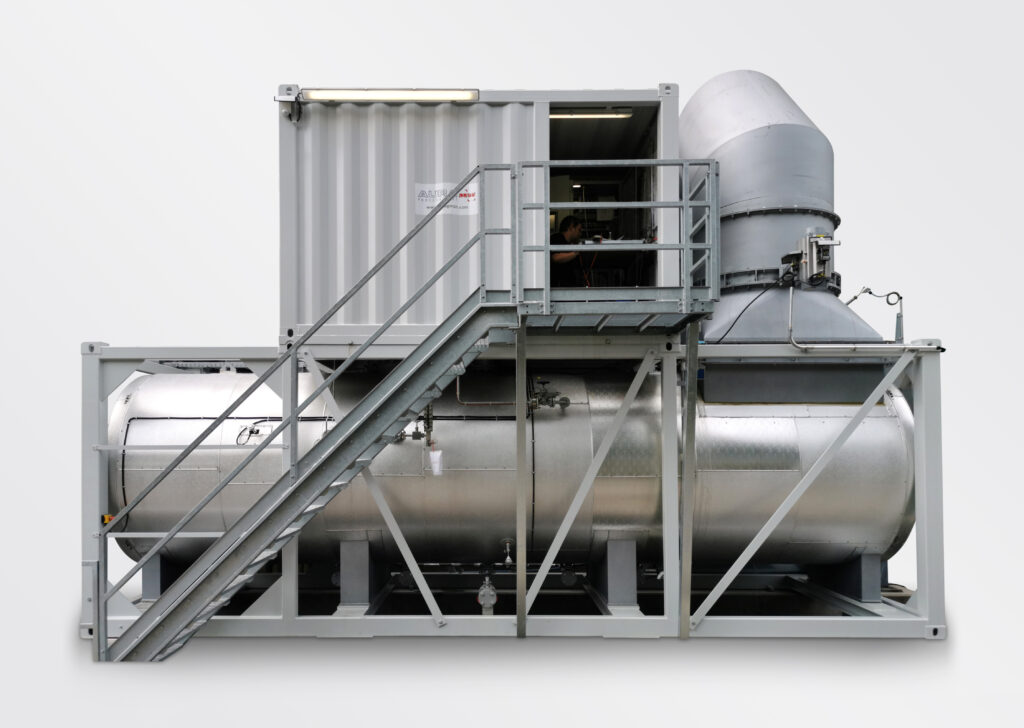

Exemplary system:

590kW, 950 kg/h

More sample Images:

(Shown in the picture: Flue-heated steam generator with 590kW, 950 kg/h).

Steam generator for waste heat recovery from flue gas. The steam generator takes heat energy from the clean gas stream and thus generates steam. Any existing fired steam generators thus become obsolete or can be used as a back-up. The waste heat recovery with this plant saves CO2 and thus sustainably protects the environment.

All AURA plants are individually designed and adapted for the respective requirements in a close and cooperative process with our customers.

System Properties:

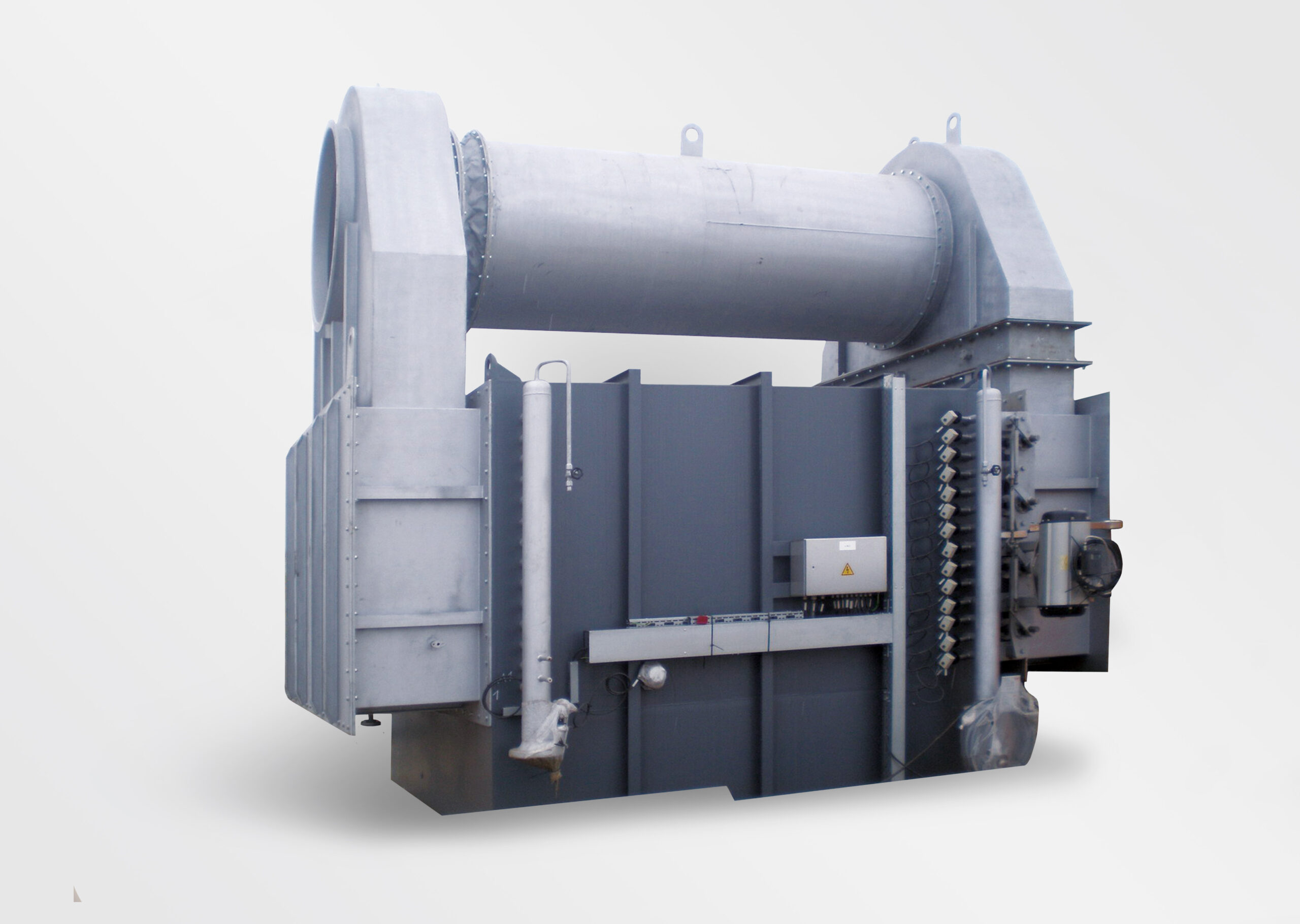

Thermal oil heating system for heat recovery from flue gas. The heating system can use flue gas with a temperature of up to 1200°C in order to make sensible use of unused waste heat. In this way processes can be made more sustainable and costs for primary energy and CO2 can be can be significantly reduced.

Thermal oil heating system for heat recovery from flue gas. The heating system can use flue gas with a temperature of up to 1200°C in order to make sensible use of unused waste heat. In this way processes can be made more sustainable and costs for primary energy and CO2 can be can be significantly reduced.

Up to 1570kW, flue gas temperature 1100 °C, thermal oil volume flow 63 m3/h and flow temperature 305°C

All AURA systems are individually designed and adapted for the respective requirements in a close and cooperative process with our customers.

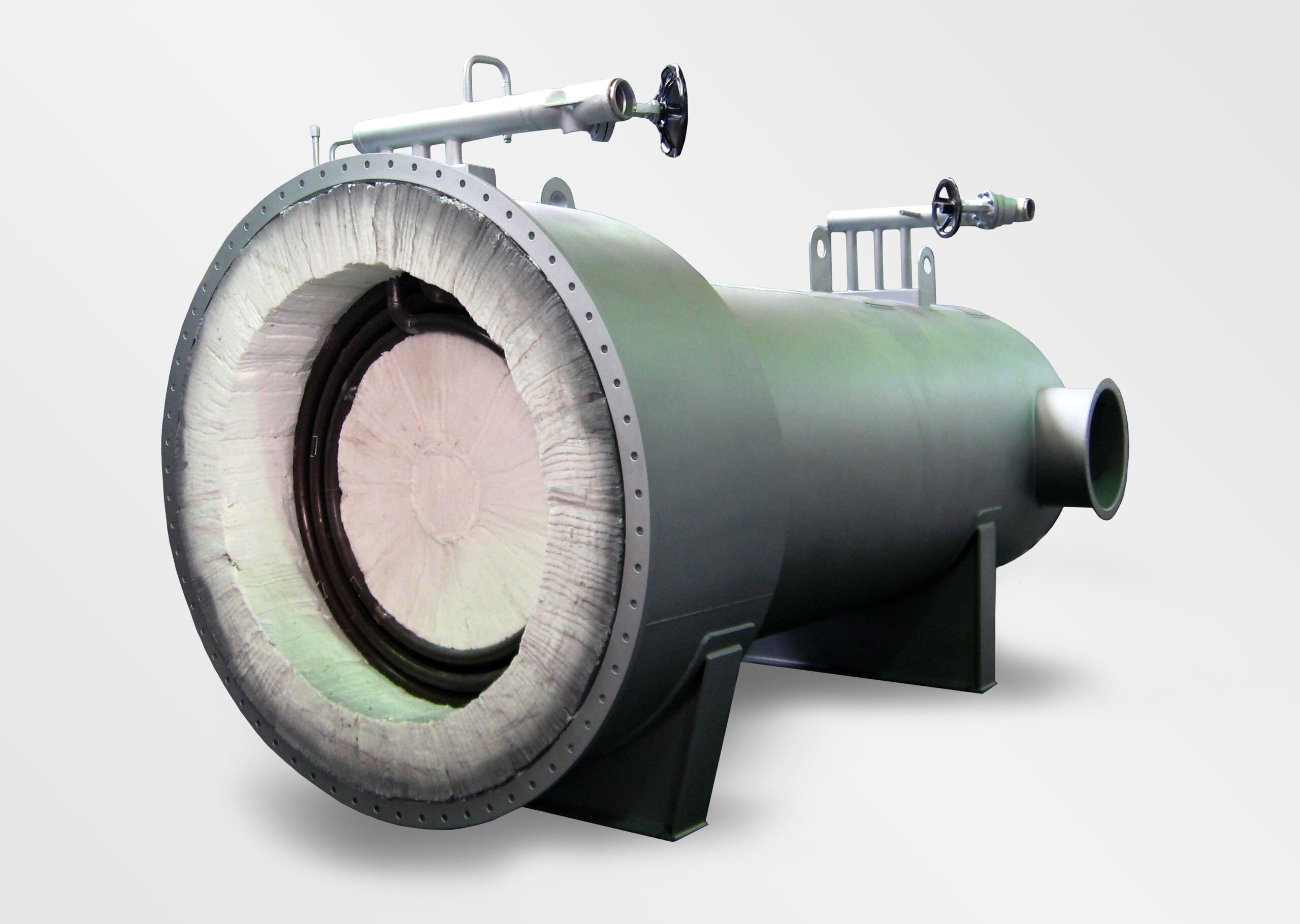

System Properties:

The use of turbines produces large quantities of flue gases and thus waste heat, which is often not utilized. Here, heat recovery can make your production not only more efficient but also more sustainable. The AURA waste heat recovery system for turbines can make the heat contained in turbine flue gases usable for other processes in a temperature range of up to 430°. Lower temperature flue gases can also be utilized with this system by installing an additional afterburner. The system can generate an output of up to 12000 kW.

The use of turbines produces large quantities of flue gases and thus waste heat, which is often not utilized. Here, heat recovery can make your production not only more efficient but also more sustainable. The AURA waste heat recovery system for turbines can make the heat contained in turbine flue gases usable for other processes in a temperature range of up to 350°. Lower temperature flue gases can also be utilized with this system by installing an additional afterburner. The system can generate an output of up to 12000 kW.

All AURA systems are designed and adapted individually for the respective requirements in a close and cooperative process with our customers.

Nach dem Klick können Sie direkt in unseren

Kalender schauen und sich einen passenden Termin

mit einem unserer Mitarbeiter auswählen.

AURA GmbH & Co. KG

Siebeinstrasse 3 (Zone 2)

76726 Germersheim, Germany